Jewelry welding machines play a vital role in the manufacturing and repair of jewelry, with applications primarily in the following areas:

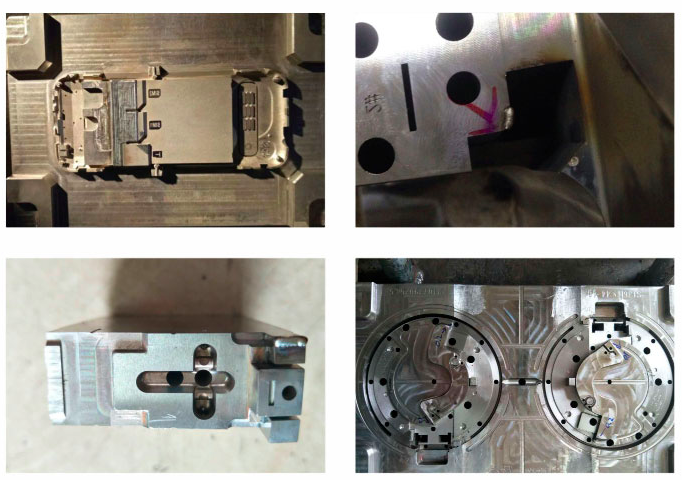

Jewelry Repair: Used to repair wear and damage in precious metal jewelry such as gold, silver, and platinum, enabling precise welding on small areas to maintain the integrity and appearance of the piece.

Fine Welding: Ideal for welding small and intricate jewelry components, such as chain links and prongs in setting work, ensuring high strength and precision in detailed sections.

Custom Design: Applied in custom-designed jewelry to meet welding needs for complex designs and fine structures, allowing for greater design versatility.

Gemstone Setting: Assists in securing metal prongs for gemstone settings, ensuring the stones are held firmly in place without causing thermal damage to surrounding materials.

Surface Refinement: Used for minute adjustments and welding on jewelry surfaces, achieving a perfect finish that enhances the aesthetic appeal of the piece.

Multi-Material Welding: Suitable for joining and welding different metal materials, including gold, silver, platinum, and palladium, meeting the demands of various material combinations.

Rapid Prototyping: Facilitates the quick creation and testing of new jewelry prototypes, enabling designers and manufacturers to validate and refine designs in a short time.

With its high precision, low heat impact, and adaptability to various materials, jewelry welding machines are essential in the jewelry manufacturing and repair industry, helping manufacturers improve production efficiency and product quality.

youmir-laser.com. All rights reserved.